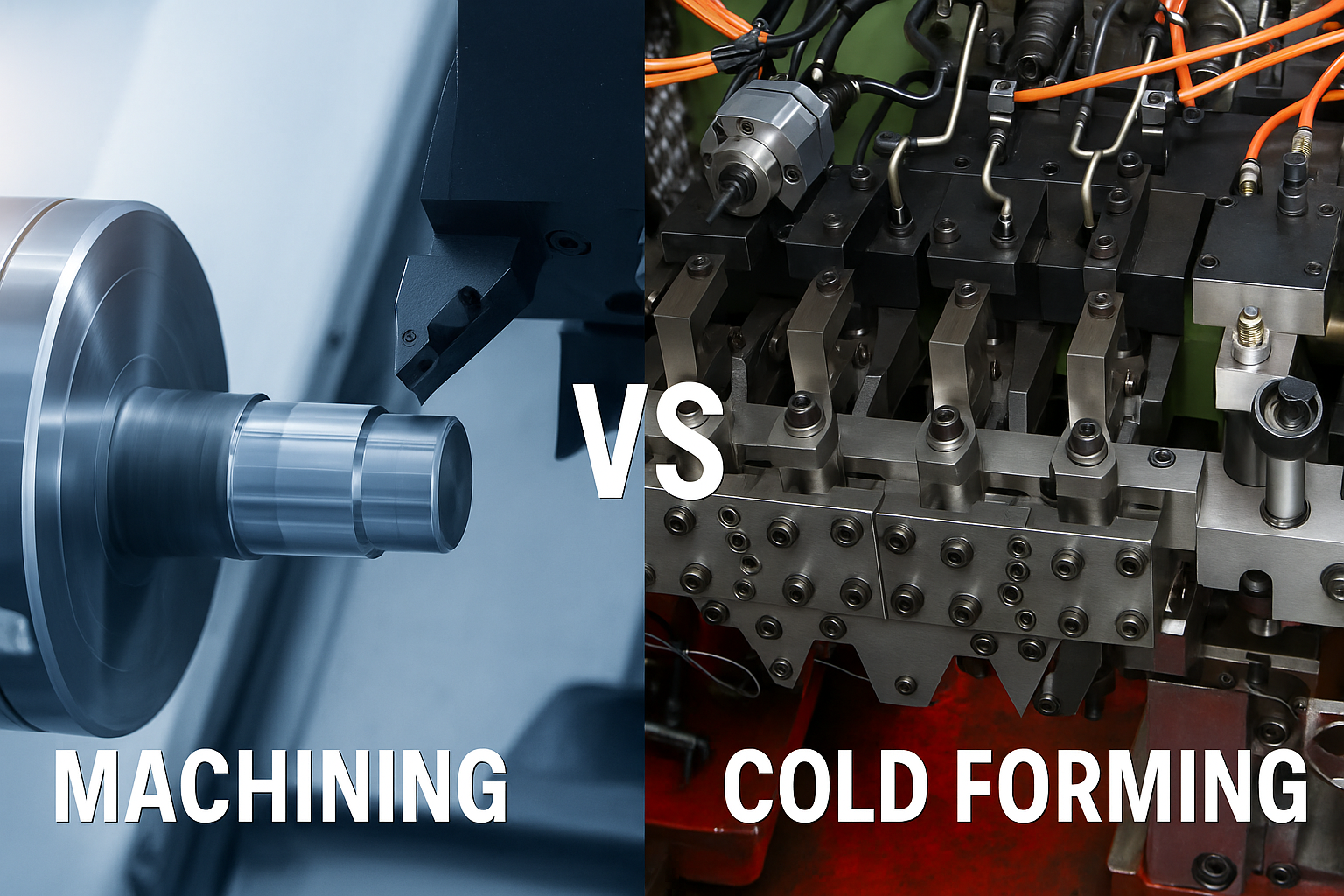

Which production method suits your need best?

In industrial production, selecting the right method determines cost, quality, and time. In this article, we compare two essential methods for mechanical parts: Cold Forming and Machining.

🧱 Key Technical Comparison

|

Feature |

Cold Forming |

Machining |

|

Process Definition |

Plastic deformation at near room temperature |

Cutting away excess material |

|

Material Usage |

Near-zero waste, highly efficient |

High material loss, especially on complex shapes |

|

Production Speed |

Very fast, suitable for high-volume production |

Slower, depends on geometry |

|

Surface Quality |

High, often no post-processing needed |

Adjustable, can reach very high quality |

|

Mechanical Properties |

Stronger, refined grain structure |

May require heat treatment to strengthen |

|

Precision |

Moderate, improved by precise tooling |

Very high, micron-level tolerances achievable |

|

Complex Shapes |

Best for simple and symmetrical parts |

Ideal for complex and multi-surface geometries |

|

Tooling Cost |

High initial investment (tooling needed) |

Lower cost, flexible tooling |

|

Part Strength |

High, fiber structure remains intact |

Lower, cutting interrupts material continuity |

|

Application Areas |

Bolts, shafts, fasteners |

Prototypes, custom machine components |

📊 When to Choose Which?

|

Requirement |

Recommended Method |

|

Mass production, cost focus |

Cold Forming |

|

Complex design |

Machining |

|

High strength requirement |

Cold Forming |

|

Tight tolerances |

Machining |

📄 Conclusion

Cold Forming: High strength, minimal waste, fast production

Machining: High precision, flexible shapes, ideal for special parts